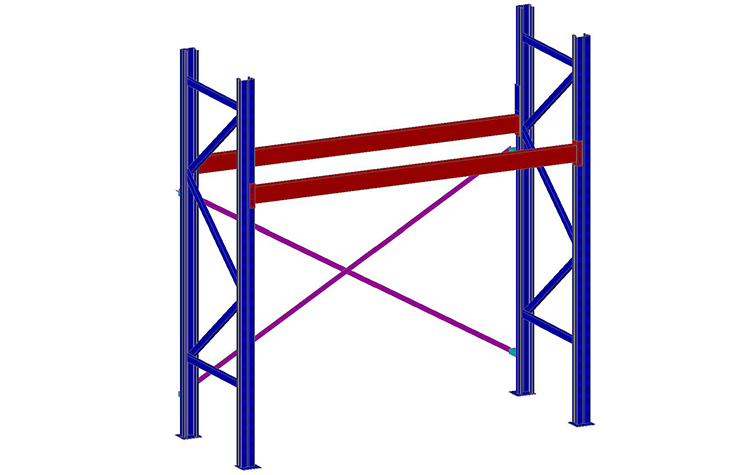

In the storage rack system, the stability of heavy duty pallet racks is directly related to storage safety and operational efficiency. When the rack is designed as a single layer (such as only one layer of beams and shelves), the lateral stability of the overall structure will be significantly reduced. This is because multi-layer racks can disperse the force through the mutual restraint of the upper and lower beams, while single-layer racks lack this support and are prone to tilt or deformation when subjected to cargo pressure or forklift collision.

Back Brace is a diagonal brace or cross brace that connects the shelf columns and beams, usually made of steel. Installing back braces in single-layer heavy duty pallet rack can effectively solve the following problems:

Enhanced rigidity: The triangular stabilizing structure disperses stress and reduces the risk of deformation of columns and beams.

Improved safety: Comply with warehouse safety regulations (such as OSHA or EN standards) to avoid accidents caused by structural instability.

Application scenarios:

Single-layer heavy duty pallet rack are commonly used to store large equipment, molds or heavy pallets, especially in environments with limited space or high-frequency access. For example, when single-layer racks in auto parts warehouses store heavy objects such as engines, back pulls can significantly improve the torsion resistance of the shelves.

Installation points:

- The back pull needs to form a 45°~60° angle with the column and beam to ensure the best support effect.

- The material thickness should match the load-bearing capacity of the shelf. It is usually recommended to use cold-rolled steel ≥2mm.

- The bolt tightening status needs to be checked regularly to prevent loosening.

In summary, adding back pulls to single-layer heavy duty pallet rack is a low-cost, high-efficiency stability solution that can make up for the design defects of the single-layer structure and ensure the long-term safe operation of the storage system.

Post time: Jul-28-2025